Coating Laboratory / Quality Control

Wet-Lab Process Control

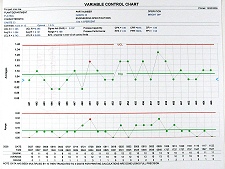

Statistical Process Control Chart

Paramount Metal Finishing Quality Policy

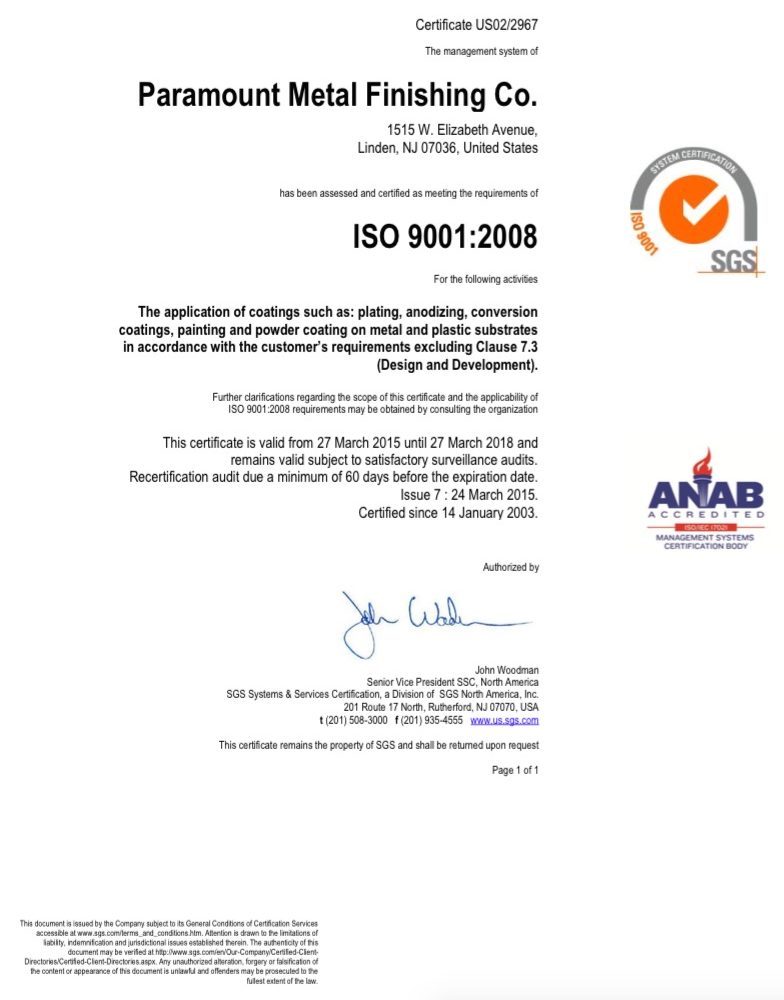

Our goal is to provide customer satisfaction by supplying unparalleled metal finishing services meeting customer requirements. We will succeed through developing our human resources, applying the best technologies, continually improving our quality management system and processes and by complying with the requirements set forth in ISO 9001:2015.

| Inspection Equipment | ASTM / MIL SPEC | Purpose | Coating |

| X-ray fluorescent | ASTM-B568 | thickness | plating |

| Kocour | ASTM-B499 | thickness | plating |

| Tabor | FED-STD-141 | hardness | anodize |

| Pencil | ASTM-B201 | adhesion | plating |

| Salt spray test | ASTM-B117 | corrosion resistance | plating, painting |

| Microscope | visual | various coatings | |

| Oven | bake test | various |

Process Control

| Titration Wet Laboratory | Solution Analysis |

| Statistical process control (SPC) | process control |

| Spectrometer | solution analysis |

| pH meter | pH determination |

| Analytical digital scale | weight tests |

| Test Specifications | SPECIFICATION |

| Sampling plan | MIL-STD-1916 |

| Adhesion paint | ASTM-D3359 |

| Adhesion plating | ASTM-B571 |

Improvement Tools Actively Employed at PMF:

- ISO 9001:2000 QMS System

- Six Sigma – problem solving & process improvement

- 5Ss – facility improvement efficiency

- Kaizan events – improvement process techniques

- Process control documents (PCD) – process control

- Statistical process control (SPC) – solution control

ISO 9001:2008 Certification

Copyright © 2019 Paramount Metal Finishing - ITAR Registered - RoHS Compliance